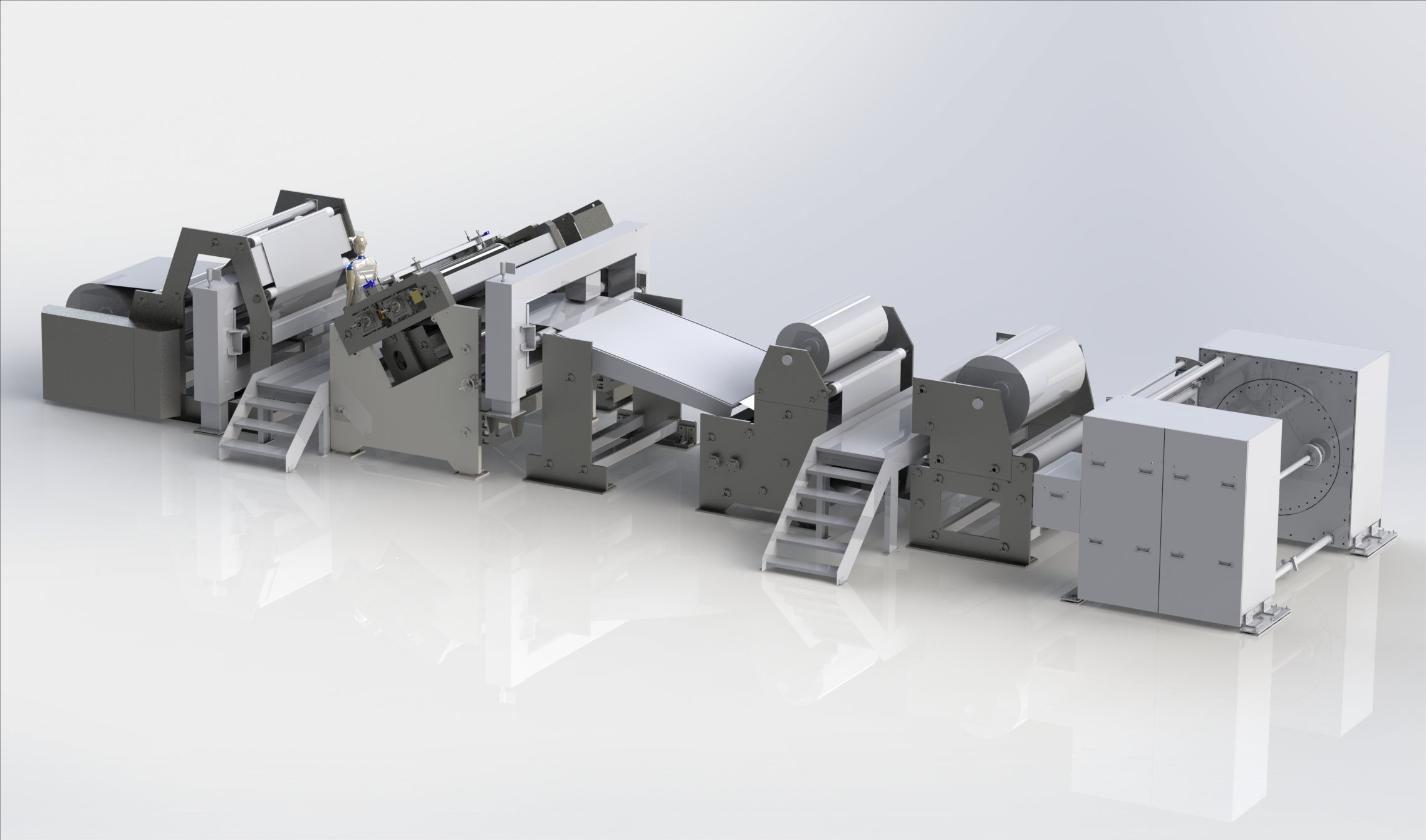

Composites technology company Cygnet Texkimp has revealed it is developing a high-tolerance reverse roll coating machine to create sub-10gsm films for the aerospace-quality prepreg industry.

The industrial-scale coater is due to be launched in summer 2017 and will be housed in Cygnet Texkimp’s R&D centre at its UK headquarters in Cheshire. Prepreg manufacturers will be able to run dedicated trials of the machine to produce material samples using their own resins and papers.

The coater’s 60” wide coating heads are tuned to sub-two micron tolerance TIR to achieve low area-weight films that can be used to create lighter, stronger composite parts.

“This is a world-class piece of kit with exceptionally high levels of tolerance, so we recognise the need to demonstrate what the technology can do for customers,” explains Cygnet Texkimp managing director Luke Vardy.

“Having the full-scale machine right here is a huge asset for us and our customers. We’re effectively de-risking their investment by proving its capabilities. Prepreg manufacturers can carry out trials of new resin formulations for example without disrupting existing production.”

Cygnet Texkimp has been manufacturing fibre-handling machines since the early 1970s, and is best-known in the industry for its creels and prepreg production machines.

“We’re well-known for our understanding of the technical fibre market and the quality of our prepreg machines. Having a high-performance coater in our portfolio allows us to offer full turnkey solutions to any entrant into the composites market.

“We can now deliver everything from creels, unwinds and rewinds, to slitting technologies and all types of materials handling equipment, to manufacturers producing components for the aerospace, automotive and sporting goods markets.”