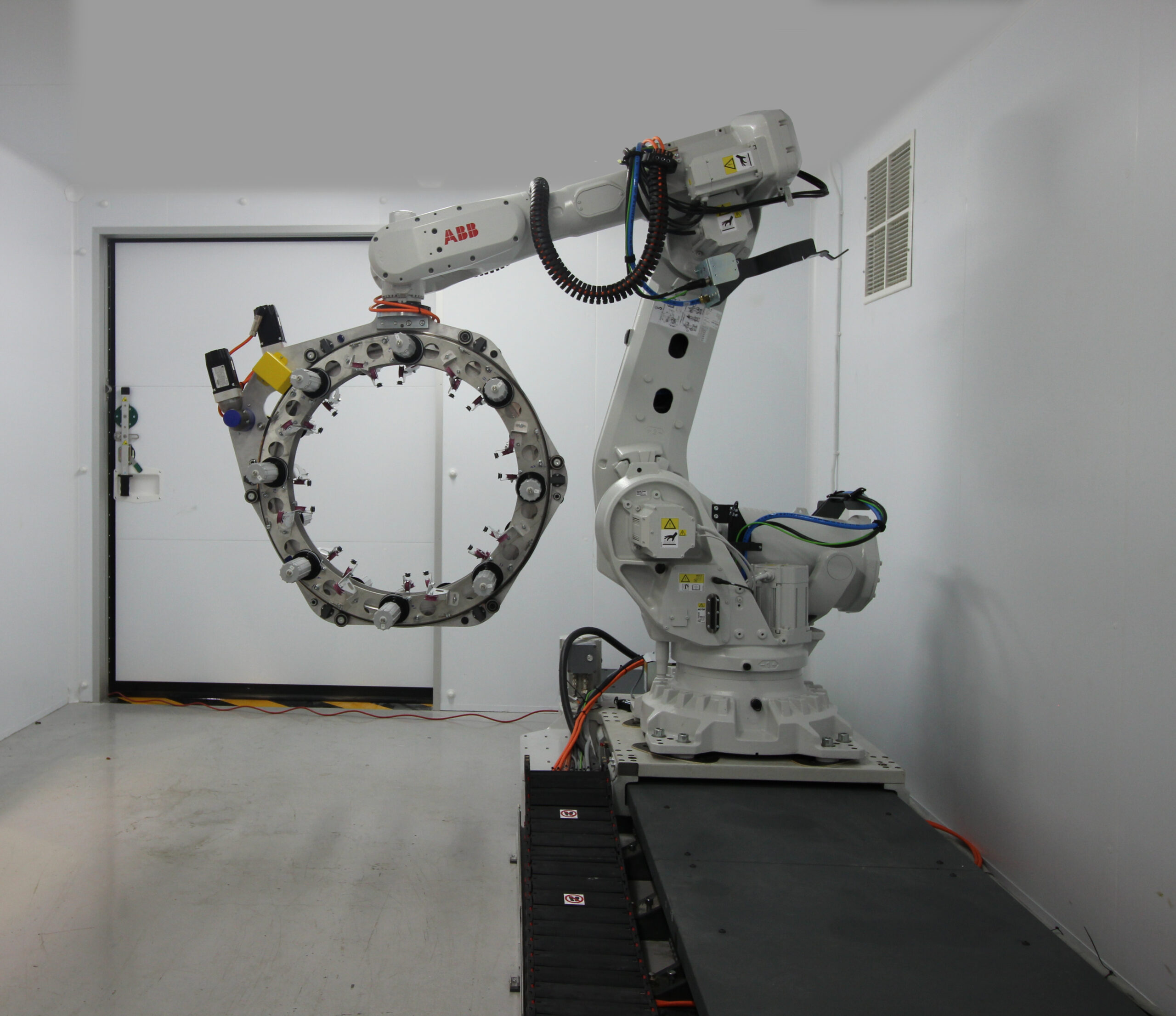

The world’s first robotic high-speed, 3D winding machine capable of making curved composite parts will be launched by composites technology company Cygnet Texkimp at JEC World in Paris next week.

The 3D Winder is a robot-mounted rotary winding machine capable of creating complex parts with a non-linear axis and with varying cross-sections. At Cygnet Texkimp’s UK headquarters in Northwich, Cheshire, the company is able to produce parts measuring up to 10 metres in length and with a profile of up to 500mm across. The full scale of the parts it is capable of producing is limited only by the application.

The machine is designed to lay down multiple tows of up to 50,000 filaments at once and trials have shown it has the potential to wind a single-aisle aircraft spar in a few minutes. It can create a wide range of components from composite fuel pipes to structural beams and aircraft fuselages for the automotive and aerospace markets.

The technology has been developed as part of Cygnet Texkimp’s KTP (Knowledge Transfer Partnership) with specialists from the Northwest Composites Centre at the University of Manchester. It is based on the 9-Axis robotic winding concept originally developed by Professor Prasad Potluri, head of the Robotics and Textile Composite Group and director of research at the Northwest Composites Centre.

“By mounting the winding mechanism onto a rotating axis, we can follow complex curves and wind multiple fibre ends around corners,” says Cygnet Texkimp managing director Luke Vardy.

“We’ve effectively revolutionised what our customers can achieve with winding.”

Instead of feeding fibres onto a rotary mandrel, Cygnet Texkimp’s winding machine uses a rotating mechanism which moves around a static mandrel and winds fibres in to create curved preforms. Dry fibres are wound in at high speeds and layered up to build 3D structures that are infused with resins to create finished parts. For more demanding applications a prepreg tape may be used to tightly control composition.

“The static mandrel doesn’t require any structural strength itself, and may become part of the final composite structure once fibres have been layered up around it. Alternatively, it can be removed to leave a hollow core.

“The art of creating strong, lightweight structures cost-efficiently using carbon fibre is all about deposition – it’s about putting down the fibre as accurately and as quickly as possible.

The machine’s developers believe it can revolutionise the way lightweight aeroplane and automotive parts are made from carbon fibre.

“We’re on the cusp of a new generation of lightweight, fuel-efficient aeroplanes and motorcars that demand new approaches to manufacturing with more intelligent materials.

“Carbon fibre gives us the opportunity to take out weight and improve strength, and 3D winding provides us with a revolutionary new way of using it efficiently.”

The 3D Winder will be showcased at Cygnet Texkimp’s Hall 5A, Booth P67