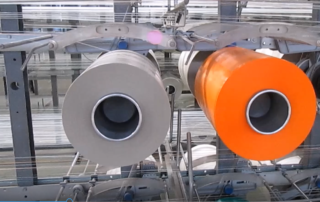

Poly Tape Creel

Cygnet Texkimp’s Poly Tape Creels feature our unique patented design for the high speed unwinding of yarns, extruded tapes and monofilaments into beamers, dipping lines and other downstream process machinery.

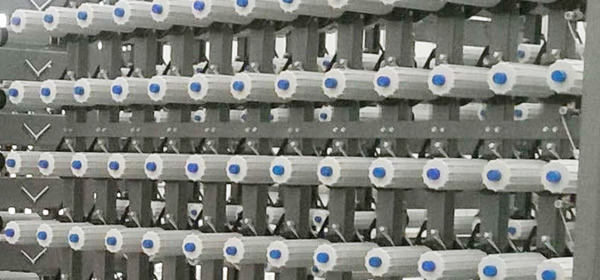

This creel can accommodate a variety of package types and can be customised to offer the right level of control for each application. Each position features tension compensation and quick-stop braking to ensure constant running tension and quick stopping without over-tensioning.

The end break stop system monitors each tape or yarn and sends a stop signal to the downstream process if a lost end is detected.

The central tension system can be set manually or electronically via an HMI unit allowing consistency of tension across the creel for all positions from full to empty.