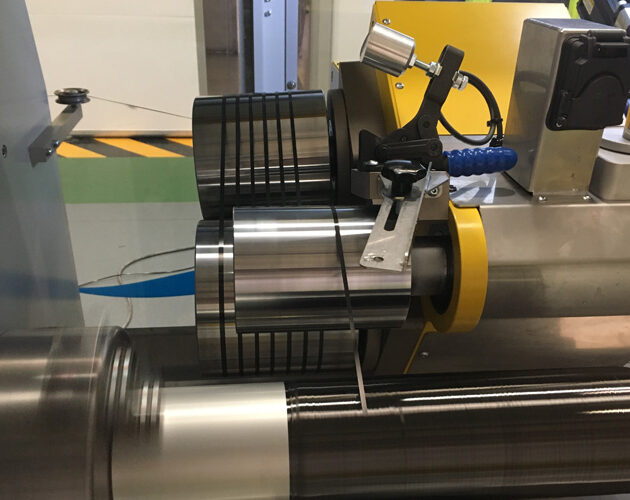

Composites technology company Cygnet Texkimp has developed a high-tension fibre winding solution to create lightweight rotating parts with greater dimensional stability at higher speeds.

The technology, which has evolved through the company’s filament winding capability, has been developed to achieve more power from high-speed rotating machinery by wrapping it in carbon fibre under high tension. This allows the final part to rotate more quickly without expanding and means that more power can be achieved from lighter parts.

Applications include high-speed motors for automotive, motorsport and aerospace and fly wheels for energy recovery.

“Our high-tension overwrapping solution has been engineered to manufacture parts where accuracy at high rotational speed is critical,” explains Tony Price, Product Director for Filament Winding and Fibre Placement at Cygnet Texkimp.

“By winding a layer of fibre at high tension around a blank part we can add an extra level of considerable strength, substantially increasing the component’s capacity for speed and endurance without adding significant weight.”

The solution can generate up to 2000 Newtons of tension and wind consistently in excess of 60m per minute and up to 100m per minute, although that is dependent on the type of fibre used. Winding at tension allows manufacturers to pack fibres more tightly and uniformly around a mandrel or part, pulling the filaments closer together within the winding pattern. The effect is that the fibre-volume ratio is increased – in this case to more than 70% – to create a lighter part that achieves maximum strength with minimum thickness.

“We’re effectively winding close to the breaking point of the fibre, and in doing so we’re able to pre-load the part to withstand greater stresses in operation,” says Tony Price.

The technology combines a driven creel system with a sequence of servo-driven rollers to generate and control high levels of force while ensuring minimal damage to the fibre. This is a crucial element of the design and reminiscent of all Cygnet Texkimp’s fibre handling technologies, because any fibre damage that occurred here would reduce the level of tension that could be realized in the part.

An automatic, real-time electronic tension control system is used to monitor and match torque and vary speed, while a purpose-engineered winding head withstands increased force. Taken to their limit, the carbon tows themselves are an elastic element in the process, adding a further level of complexity for the technology to manage.

Together, these technologies also allow for the desired winding tension to be isolated from the tension needed to unwind the fibre from the package. The package is unwound at a suitable tension to ensure reliability and only after that is tension increased to achieve the desired properties in the wound part.

The solution is capable of processing single- or multi-tow carbon, glass or ceramic fibres and can accommodate dry winding, wet winding and thermoplastic or thermoset towpregs, with towpregs allowing for greater speed and efficiency in the manufacturing process.

Cygnet Texkimp’s high-tension winding solution is now available for trials at the company’s Innovation Centre in Cheshire, UK.

Article Featured on JEC Composites