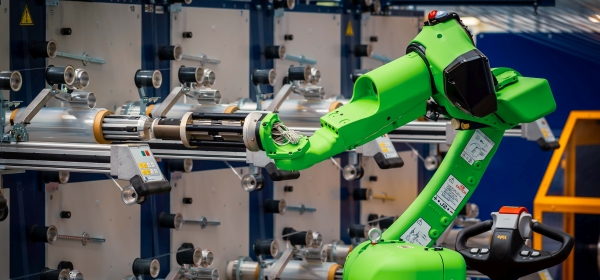

Packaging & Palletising Systems

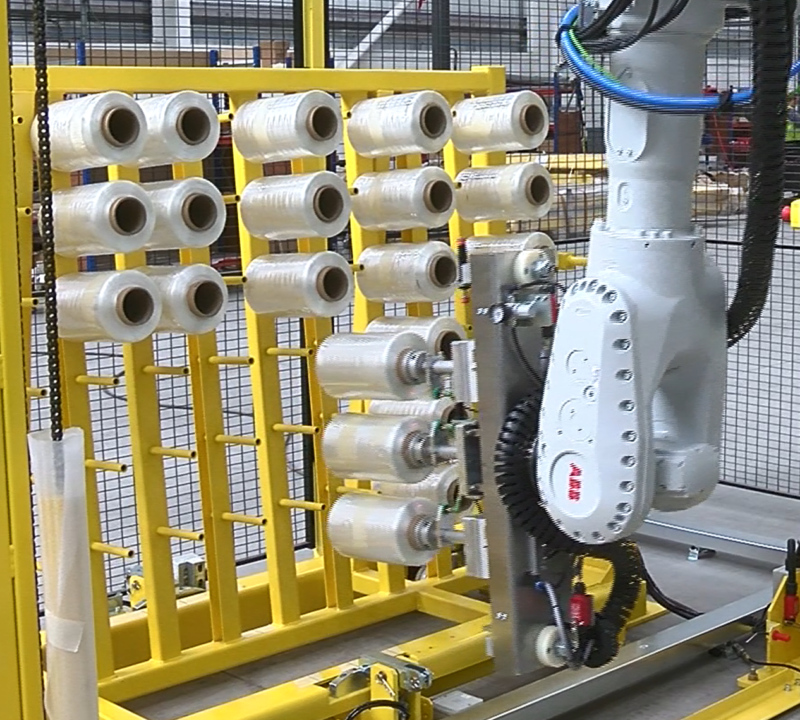

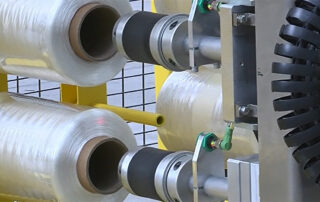

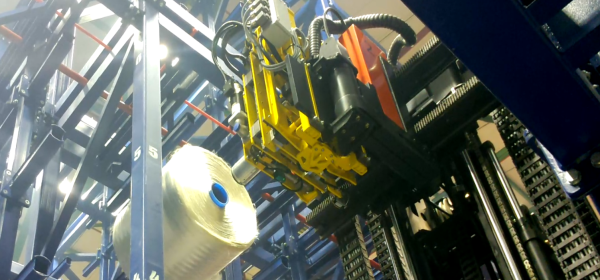

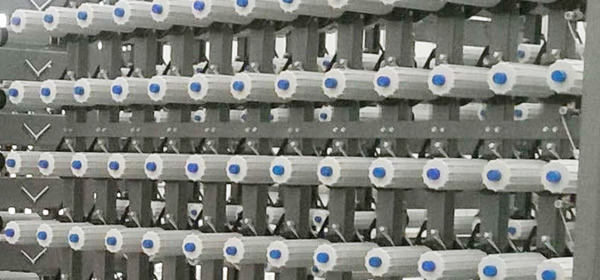

Cygnet Texkimp’s bespoke Packaging and Palletising Systems are fully automated systems that use robotics to manage packages of fibre off a production line and prepare them for shipping or storing without the need for human intervention.

These highly customised solutions are designed to considerably reduce the need for manual handling and operator input in order to increase production efficiency and factory safety and eliminate damage to the fibre, tape or yarn caused by human touch or bumps and scrapes.

Packages can be retrieved from a winding head, labelled or RFID-tagged for inventory control, inspected, weighed, measured and sorted, before being wrapped, packed and palletised, all using the pre-programmed robotic technology enhanced by safety and vision systems.