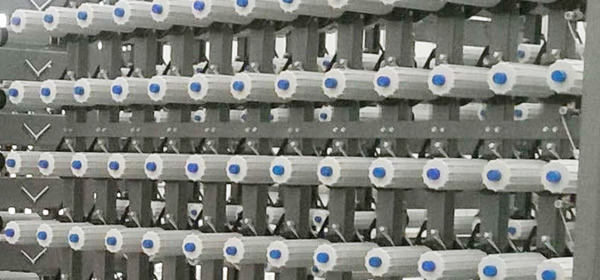

Tyre Cord Creel

Cygnet Texkimp’s customisable tyre cord creels are used for high-speed unwinding of tyre cord from random or precision cross-wound packages into weaving processes or single cord treatment lines.

These robust mobile or fixed-position creels use a mechanical brake system to maintain the yarn under constant controlled tension as bobbins are unwound from full to empty.

Tension can easily be set centrally or individually for each position, and controlled package braking for high speed, single end dipping processes can be activated without applying additional tension to the fibre.

Each creel features optimal yarn paths to eliminate twisting, roping and crossing; ergonomic package holders to allow easy loading and doffing; and ceramic guides to reduce fibre damage.

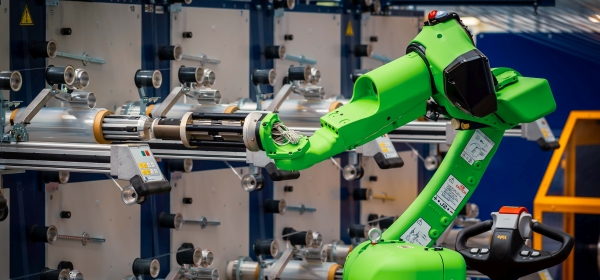

Automated features can also be combined with the creel system to enhance efficiency and productivity. These include offline loading from a trolley or mobile creel and material traceability and tracking.