Creel Loading Systems

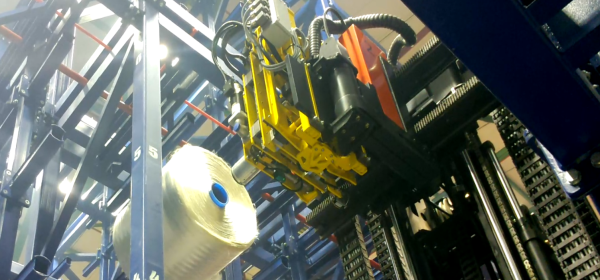

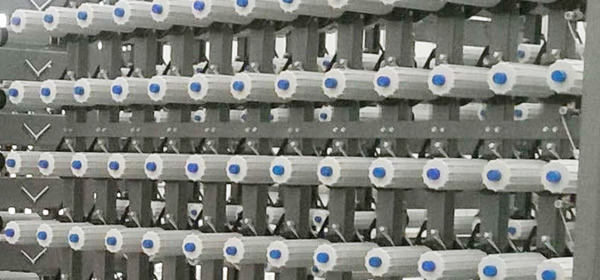

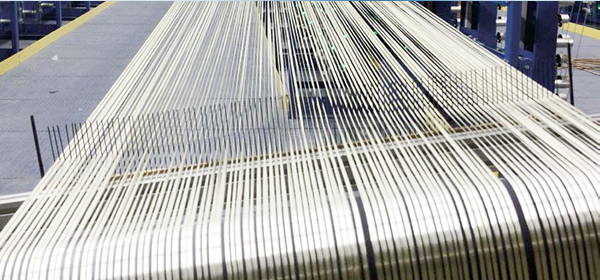

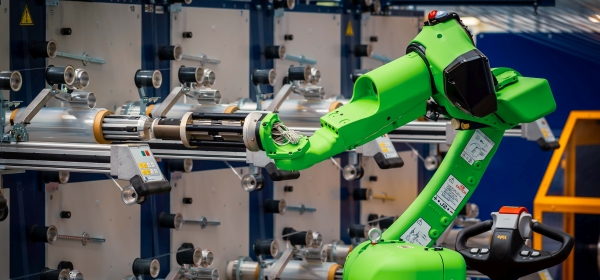

Cygnet Texkimp’s creel loading systems utilise standard 6 axis industrial robots and can incorporate a 7th axis to allow loading of more positions. These types of systems are used in conjunction with mobile creel modules where the creel runs in a running and reserve configuration. While the creel is running the reserve creel modules can be loaded into the creel loading system and packages of yarn or fibre can be loaded. Typically used in weaving or beaming applications in the tyre cord or carpet manufacturing process.

Systems usually have two loading areas, one on either side of the robot. This allows the robot to run 100% of the time as it allows operators to load/unload one side of the system while the robot is loading the other side. Turntables can be used to automatically rotate the creel module to allow access to both sides for loading.

RFID and or barcode systems can be incorporated to enable full traceability from the start of the process to the finished product. These systems also allow inventory management and can be linked to existing data management systems.

For fixed creel applications, Cygnet Texkimp recommends our Robot-AGV system. Please refer to the AGV section of our website for details.