Multi Axis Winding

Cygnet Texkimp’s Multi-Axis Winder is a high-speed winding machine capable of winding technical fibres including carbon, aramid and glass quickly and accurately into strong and lightweight composite parts for automotive, aerospace, rail, sailing, construction, wind energy.

Like the 3D Winder, this technology addresses the need for faster, lower-cost ways to manufacture consistent and repeatable composite parts.

The Multi-Axis Winder is designed for the high-rate production of linear structures, such as tubes and masts, but it is not capable of the more complex, curved shapes offered by the 3D Winder.

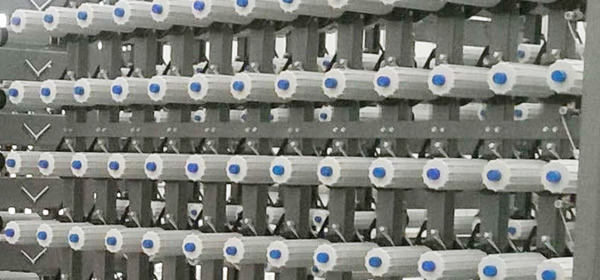

Multiple fibre tows are laid down rapidly around an inner core to build up structures quickly and with a high level of control and accuracy. The technology allows manufacturers to run dry fibres as well as pre-impregnated tapes and offers a compelling alternative to braiding or conventional filament winding.

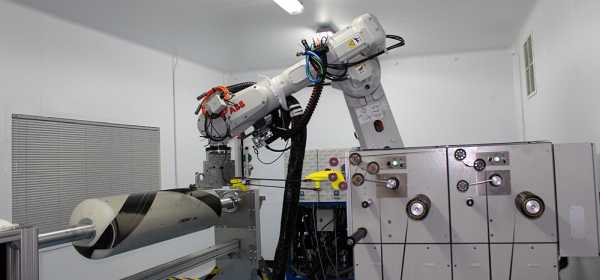

This machine is ideally suited for use with an automated production cell – including robotic loading and unloading technology – to improve process efficiency as part of an integrated manufacturing system.