At the CAMX exhibition in Anaheim 17-20 October, composites technology specialist Cygnet Texkimp will showcase its latest filament winding and slitting solutions alongside the composites recycling technology, DEECOM, which has been shortlisted in the CAMX Awards.

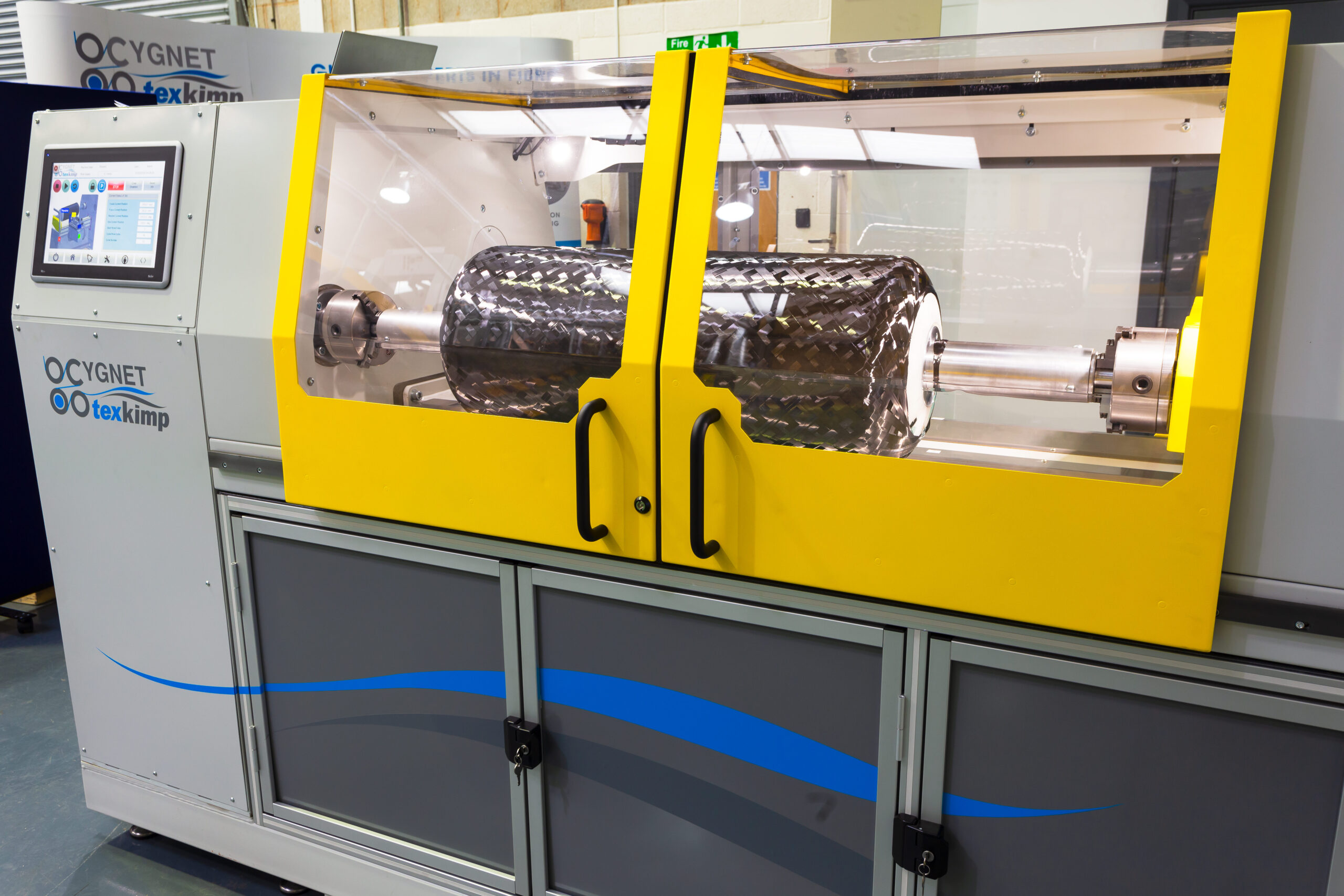

Cygnet Texkimp specialises in the design and manufacture of downstream processing equipment including filament winding, multi-axis winding, prepreg, coating and slitting machines. The company will feature its high-tension winding solution: the latest development in its filament winding product range which also includes high-speed, multi-axis and 3D winding machines.

Visitors will be able to find out more about the company’s approach to winding fibre at extremely high tension to create composite parts that perform well under intense forces, such as pressure, speed and rotation.

“We developed our high-tension winding technology in response to a number of enquiries from manufacturers looking for ways to increase the strength and resistance of their composite parts without adding weight or compromising fibre integrity,” explains Cygnet Texkimp CEO Luke Vardy.

Delegates will also have the opportunity to learn about Cygnet Texkimp’s high precision slitting technology after the company built a production-scale Slitter Spooler Rewinder machine at its UK-based Innovation Centre to demonstrate its capability and offer industry trials.

The machine draws on Cygnet Texkimp’s depth of experience in handling complex technical fibres to deliver high-accuracy slit tapes consistently and reliably and is expected to attract interest from manufacturers in the aerospace and high-end automotive industries where high precision slit tapes are used to manufacture critical components using filament winding, ATL (Automatic Tape Laying) and AFP (Automatic Fibre Placement).

Finally, the company will also showcase the fibre reclaiming and recycling solution, DEECOM, which it is developing specifically for the composites market. DEECOM is an innovative technology that uses superheated steam to reclaim composite fibres and resins from wound parts and offers the potential for them to be reused in the manufacture of new parts. The technology has been shortlisted in the Unsurpassed Innovation category of the CAMX Awards and will be displayed in the Awards Pavillion.

“The quality, length and consistency of fibres we’re able to reclaim make DEECOM a truly game-changing solution for composites manufacturers and end users working to address the major challenges of sustainability, supply and waste reduction,” says Luke Vardy.

“Through the processes of reclaiming and reusing, DEECOM provides the possibility of using every carbon fibre multiple times. Giving composite fibres multiple lifecycles means massively reducing their lifetime cost and environmental footprint and create a more abundant and consistent supply of carbon fibre.”

Cygnet Texkimp will be exhibiting at CAMX Booth P65 and in the Awards Pavilion, Anaheim Convention Centre, CA, 17-20 October 2022. For more information, visit www.thecamx.org