Machine builder Cygnet Texkimp has launched a programme of research into advanced filament winding technology to make complex parts for the aerospace market.

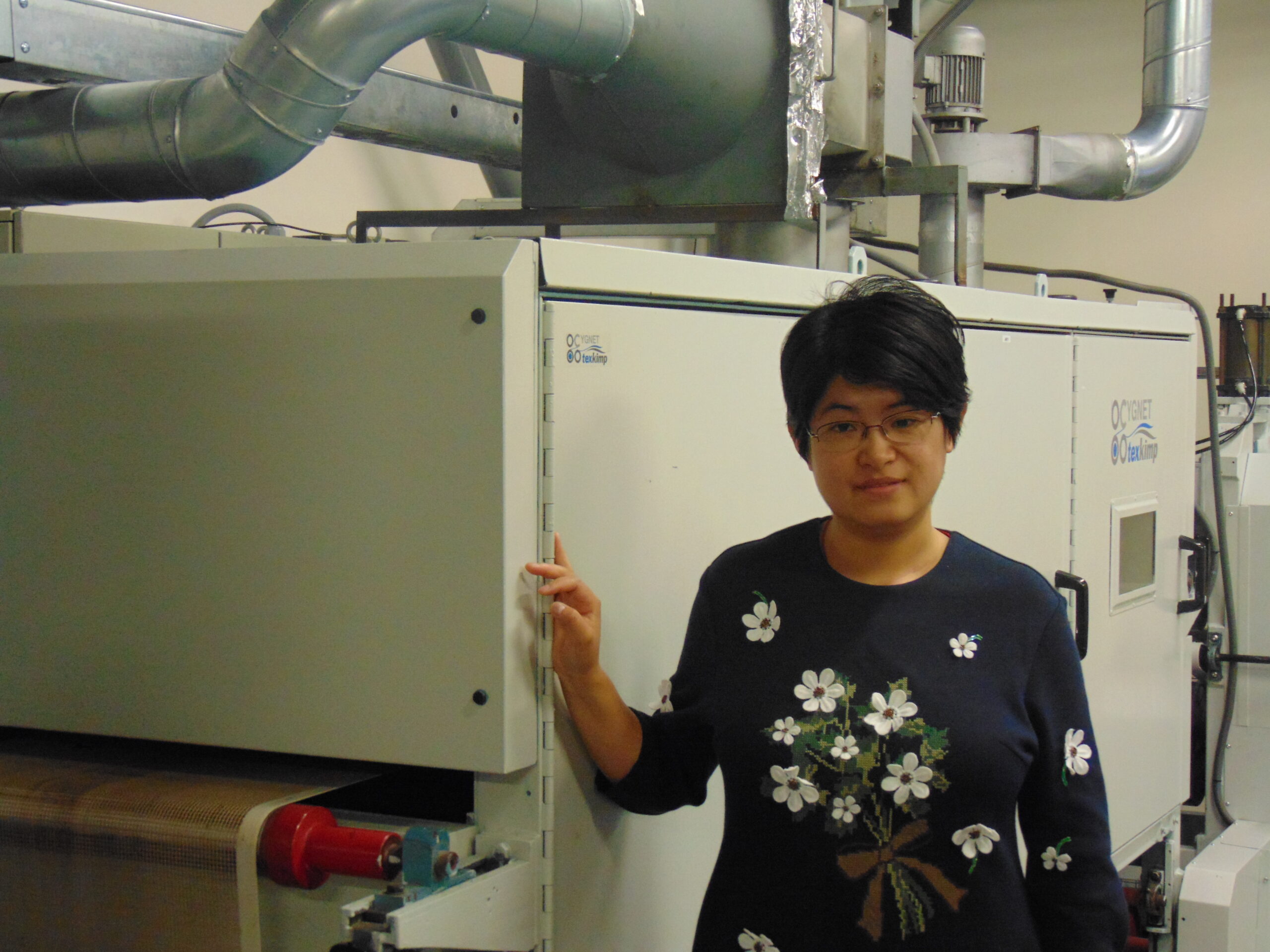

The company has appointed PhD graduate and composites academic Yan Liu to lead the trials as part of its KTP (Knowledge Transfer Partnership) with Manchester University. She has spent the last three years carrying out detailed studies into composite manufacture, including the nano-reinforcement of carbon fibre composites.

The two-year KTP study will focus on the development of Cygnet Texkimp’s robotic multi-filament winding machine, which is designed for the high-volume manufacture of carbon fibre parts.

“Yan is extremely accomplished in terms of new and innovative thinking in this area, and we are excited to have her on board,” says Cygnet Texkimp’s technical director Luke Vardy.

“This promises to be a significant and influential programme of research that we expect to have a considerable impact on the future of high-volume, complex part manufacturing.”

The company is seeking part manufacturers to collaborate with in order to develop the technology to specific market requirements.

“Our objective for these trials is to develop a truly cutting-edge way to manufacture complex aerospace-grade parts accurately using carbon fibre,” explains Vardy.

“Controlling the process robotically gives us a way of achieving exceptional levels of consistency and repeatability, cost-effectively and at high speeds.”