AGV Systems

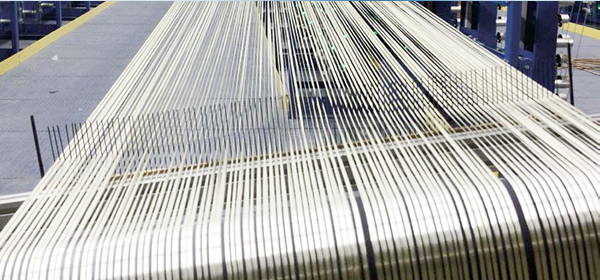

AGVs (Automated Guided Vehicles) are typically automated fork lift trucks that use laser scanning technology and reflectors to navigate the factory environment. Cygnet Texkimp’s AGV systems are most commonly used to transport large packages of fibre or pallets of yarn around a plant and to control inventory. These systems are often used in conjunction with creel loading or winder unloading systems.

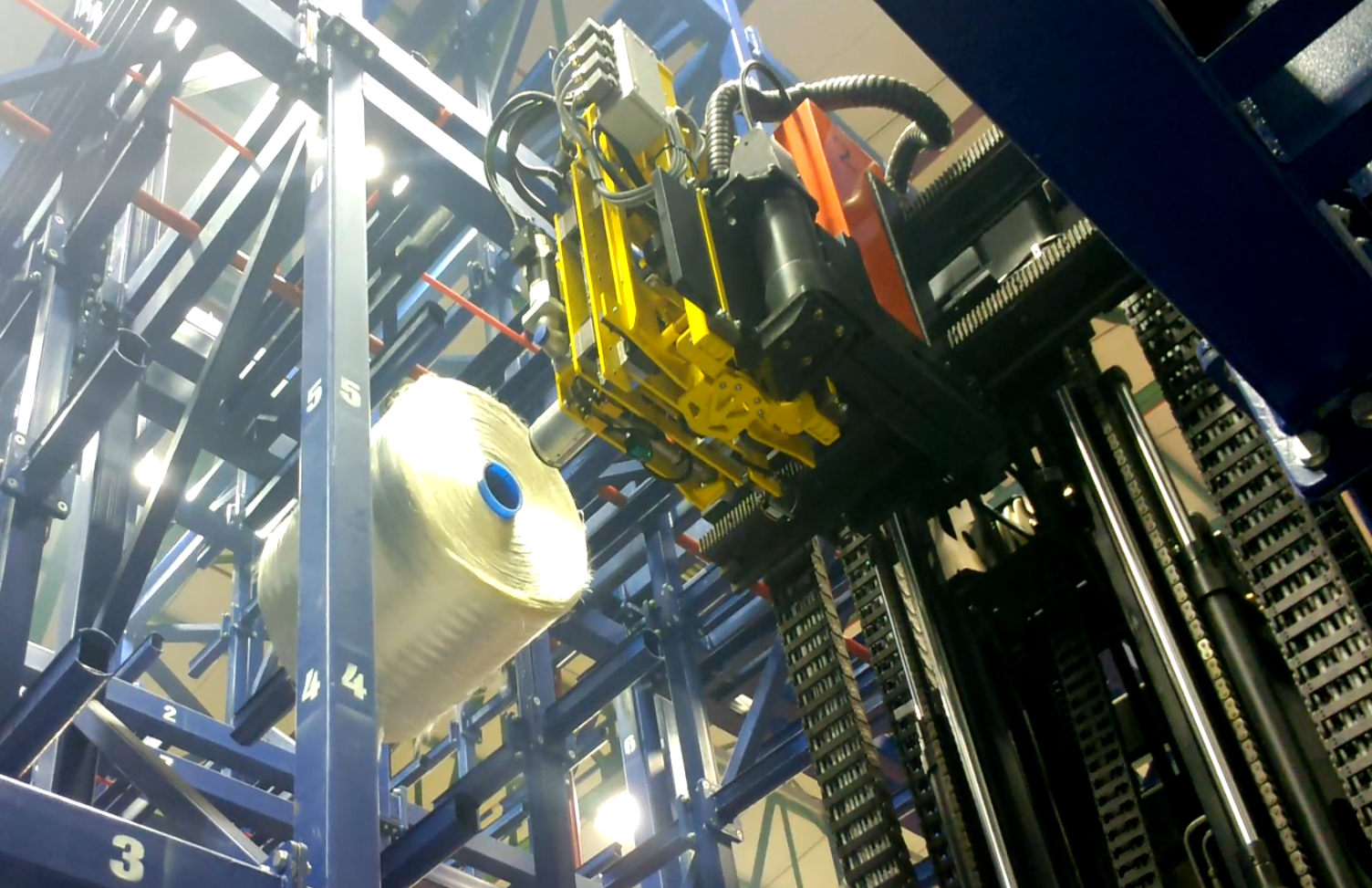

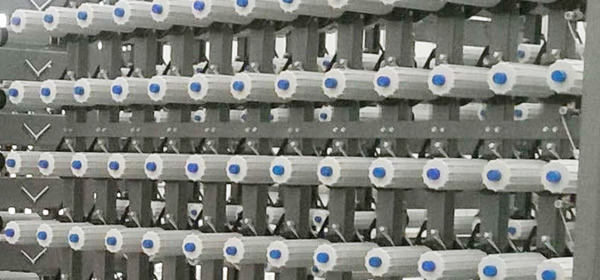

A modern carbon fibre line, for example, will process large packages of fibre weighing up to 500Kg and incorporate a creel spanning upwards of 1000 positions. Our AGV systems can be used for the following applications:-

- Collecting PAN (Poly Acrylo Nitrile) packages from winder area

- Deliver PAN packages to a storage area

- Collect from storage and deliver to creel area

- Load creels

- Complete traceability and inventory management

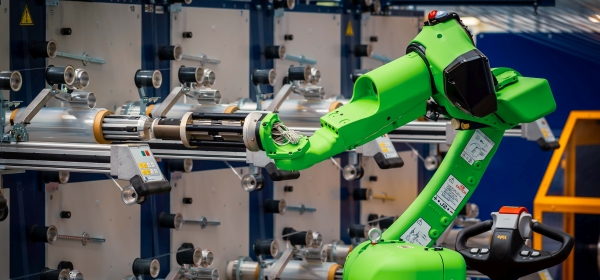

Robot-AGV Systems

Cygnet Texkimp’s Robot-AGV systems are designed to suit the application and have been supplied to load/unload products of up to 100Kg. Recent developments in battery technology have allowed us to integrate standard industrial robotics with our existing AGV systems. Our robot-AGV systems use opportunity charging where the AGV automatically docks with the charge unit. Typical charge time of around 3 to 4 minutes is standard and to charge the unit from nearly empty to full is possible in under 10 minutes.

These systems can be used for loading and unloading creels, winders, cabling and twisting machines, and shelving and racking structures. They can be programmed to follow a pre-determined route, which can be changed easily according to the task it needs to perform.

Using safety laser scanners and encoders, the system is able to plot its exact location and detect obstructions that cause it to slow down or stop moving immediately. Our systems are regularly used for loading and unloading processes alongside operators performing manual tasks.