Composite Recycling

Composite components such as carbon fibre, glass fibre, and aramid cannot be landfilled due to their hazardous nature. The established and historic methods of disposal are chemical recycling (solvolysis, using solvents) or burning (pyrolysis), which weakens the fibres rendering them low grade and unsuitable for many applications, but allowing them to be remanufactured to a lower grade composite for us in sports equipment, concrete, or outdoor furniture, for example.

The Challenge

The composites industry worldwide already reports a massive shortage in supply of these materials, both demand and cost is high. Demand is projected to grow over the coming years, along with waste.

Cygnet Texkimp is pleased to offer its novel composite recycling solution leveraging over a decade of research and development by B&M Longworth into its DEECOM® pressolysis, where valuable fibre can be reclaimed from the resin matrix without burning, chopping, or weakening. This allows for reprocessing and remanufacture into high grade items whilst meeting safety and strength demands.

What is DEECOM®?

DEECOM® is an exciting innovation that uses a thermo-cyclic form of ‘pressolysis’ to reclaim value waste streams from challenging thermoplastic and thermoset polymers. In its basic form, DEECOM® relies on super critical steam and swings of compression and decompression to attack the surface area of organic material causing a physical ‘fracturing’ of the polymeric contaminant. This polymer, in the form of yarn, resin, or binder, for example, is then removed from the underlying component, which can be a metallic, carbon fibre, glass fibre, or other polymer part.

Quite simply, DEECOM® reverses the bonding of component fibre with resin/binder

The format you put into DEECOM® is the format you’ll get out, for example;

Woven fabric with resin → woven fabric without resin.

Short, chopped offcuts with resin → short, chopped offcuts without resin.

Continuous, hooped fibre with resin → continuous, hooped fibre without resin.

Filter blocked with frozen polymer → filter 100% clear of contamination.

Using DEECOM®, there is no need to interact with the original component or fibre, thus reclaiming near-virgin quality materials and enabling up to 100% circularity.

What is ‘pressolysis’?

“pressolysis; the reduction of a material to its plasmic state using pressure”

This approach to materials recovery is completely state-of -the-art, it’s so novel that a new British Standard has now been approved by BSI to acknowledge pressolysis as a new method and to recognise that this technology should not be classified alongside any of the established methods of recycling such as pyrolysis, solvolysis, hydrolysis or mechanical – it is none of these.

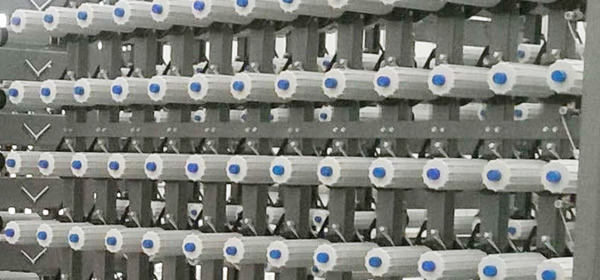

What does DEECOM® look like?

DEECOM® technology is a process, not a specific machine. This means that units can be designed for purpose, without shape, size, design or fuel constraints. Our team will work with you to create a truly bespoke solution, based on your space, utilities, feedstock, preferred output and budget.

For more information on how we can support your business, contact info@cygnet-texkimp.com