Integrated slitting technology widens accessibility to thermoset tapes

In April this year, fibre converting expert and machinery manufacturer Cygnet Texkimp will unveil a production-scale Slitter Spooler Rewinder machine at its UK Innovation Centre, where the company intends to prove the capability of its technology in comprehensive trials with prepreg converters and component manufacturers.

Graeme Jones and Peter Bugeja from Cygnet Texkimp’s Wide Web Converting division explain why the company has invested in the demonstration technology and how it works.

Prepreg slit tapes are used in a variety of applications and the process of slitting UD (unidirectional) prepreg material is essential to several markets, most notably aerospace and automotive where slit tapes are being used to manufacture critical components using filament winding, ATL (Automatic Tape Laying) and AFP (Automatic Fibre Placement).

Enabling product development and market expansion

Our motivation for building this demonstration machine is that it allows us to prove very clearly what this technology can achieve. To do so using the customer’s material and specifications means that it will be a valuable source of product development in a market poised for significant growth.

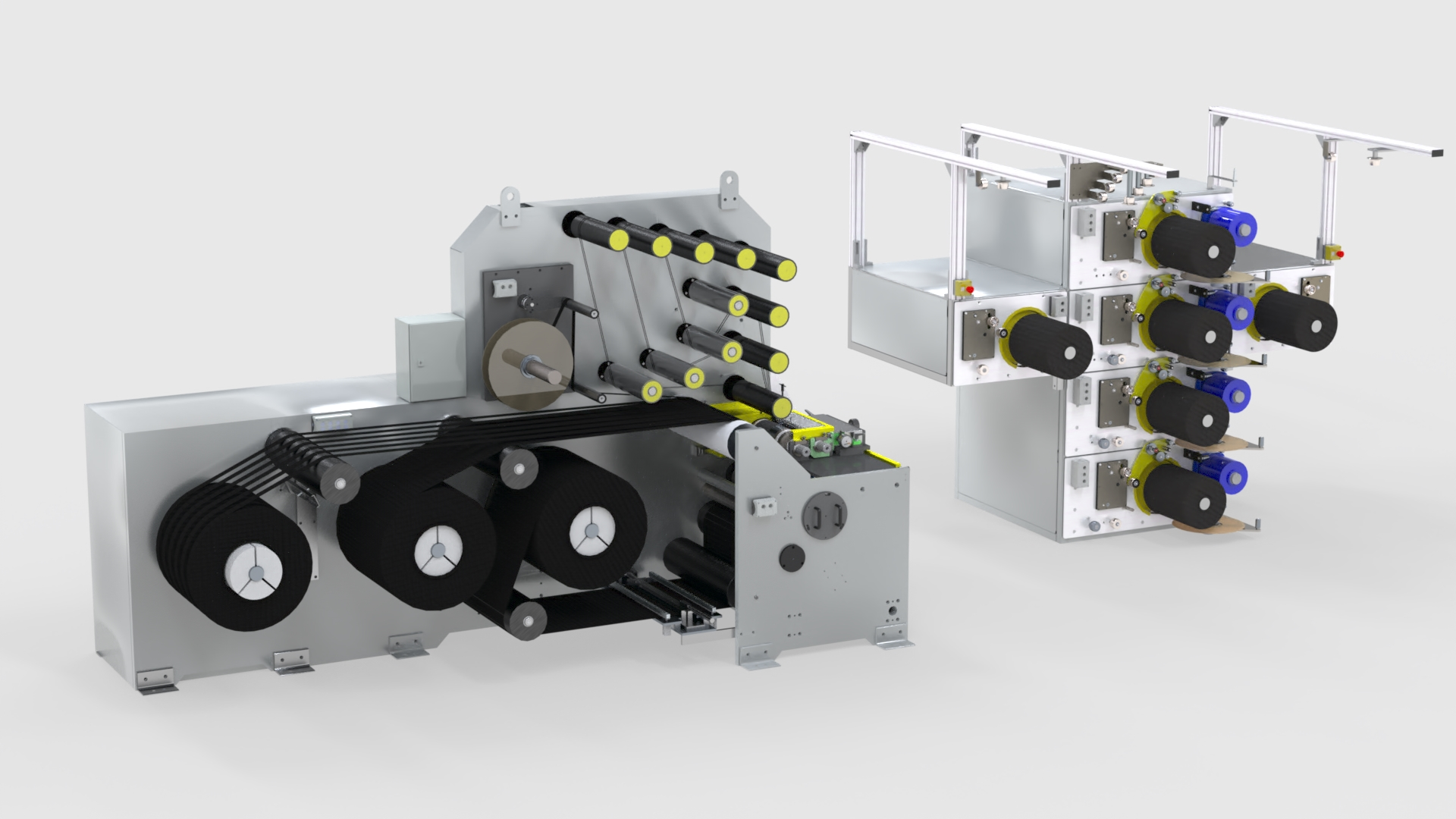

Cygnet Texkimp’s Slitter Spooler Rewinder has been developed specifically to slit continuous thermoset UD carbon fibre prepreg into tapes, although it is compatible with many other materials. The production-scale machine that will be housed at the company’s Innovation Centre has been designed to slit four tapes but is scalable to 48 tapes with the addition of modular winding heads.

It is capable of slitting prepregs and winding in traverse wound (spooled) and straight-sided (pancake) formats. It offers the capacity to slit at typical widths of 3.175mm (1/8”), 6.35mm (1/4”), 12.7mm (1/2”) and 25.4mm (1”) for spooled formats and 50mm (2”) to 610mm (24”) for pancake formats. Slit widths outside these typical sizes can also easily be accommodated.

As an additional benefit to the prepreg converter, the equipment will also convert wide rolls of poly to be used as the interleaf in the finished prepreg spools.

Handling considerations

The technology draws on Cygnet Texkimp’s depth of experience in handling complex technical fibres to deliver high-accuracy slit tapes consistently and reliably. Thermoset prepreg is known to present challenges in handling and processing. This is not only due to its tackiness or stickiness but also to the fact that fibres in a thermoset prepreg are still pliable within the uncured resin matrix and are therefore prone to dimensional instability if handled incorrectly. This can lead to fibre separation and damage in the form of fraying at the edges of the material. Known as material stringers, these can, if left unchecked, result in problems further down the process, and ultimately jeopardise the quality of the finished part.

The Slitter Spooler Rewinder is the result of decades of engineering expertise and understanding of material behaviour. Fundamental design features such as its cantilever and slitting arrangements, tape handling, integrated splices and drives logic are configured to enhance its operational efficiency and make the technology operator-friendly without compromising the quality of the finished material.

These considerations are intended to ensure that the machine runs continuously and with minimal material scrappage, resulting in less downtime and greater cost effectiveness for prepreg converters and part manufacturers.

Modular construction

Another important design feature is the machine’s modular construction. This allows the converter to start operating with as few as four winding heads but gives them the option to expand up to 48 winding heads at a later date.

Operating with just four heads is entirely realistic because the technology has been constructed to allow operators the flexibility to convert large rolls of prepreg over several passes. This means that tapes can be slit from the end of a wide reel and the remaining un-slit material can be rewound and used on the unwind for the next pass. In practical terms, this makes the Slitter Spooler Rewinder essentially a single-stage process.

Making slit tape accessible to more markets

Traditionally, slit tape production has been outsourced to specialist slitting companies. The costs and practical considerations involved in transporting and storing prepreg material (in the case of thermoset prepregs this must be in climate-controlled conditions) to and from the site where slitting takes place means that slit tapes have tended to be used only at the highest end of the composites market.

Our technology allows manufacturers to integrate the slitting process into their own production environment, immediately cutting the cost to the end user and therefore giving them access to a wider market including high-volume automotive. Having the resources to convert prepreg onsite also gives manufacturers complete control over production quality and speed, which enhances profitability. If you can slit, spool and ship the prepreg as soon as it’s manufactured, then the whole process becomes more simple, efficient and profitable.

Cygnet Texkimp’s Slitter Spooler Rewinder has the potential to significantly impact the landscape of slit tape production. We hope that making the machinery available for trials will allow us to demonstrate the market-leading quality and performance we are achieving. In doing so, our intention is to help broaden the composites industry’s understanding of slit tape production while accelerating product development and adoption.

Graeme Jones is a Product Director and Peter Bugeja is a Product Manager. Both are specialists in Wide Web Converting at Cygnet Texkimp.

For more information, visit www.cygnet-texkimp.com or email info@cygnet-texkimp.com