Filament Winder

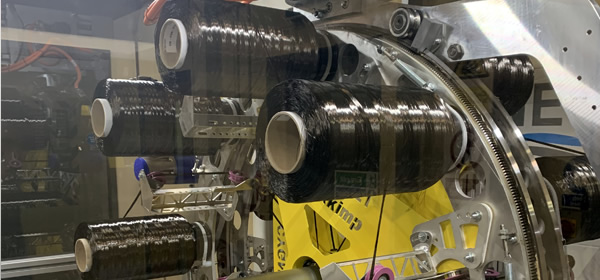

Cygnet Texkimp’s Robotic Filament Winder combines a conventional filament winding approach with robotics to make the process more flexible in terms of the size and shape of structure that it can manufacture.

This machine uses a robotic arm to feed fibre into the winding mechanism from multiple axes and can be engineered to deliver very high levels of tension.

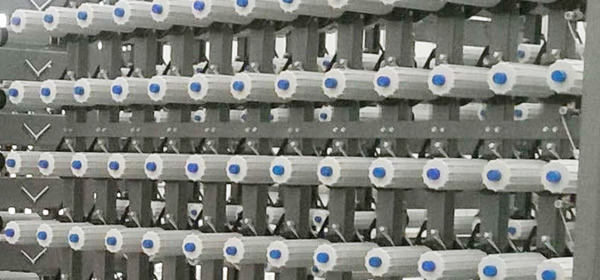

A driven creel can be incorporated into the system to allow fibre at each position or axis to be tensioned individually to control the feed and deliver a high level of accuracy and consistency. This also means the speed of each feed can be varied to deliver high resolution and create small-scale features or complex geometries.

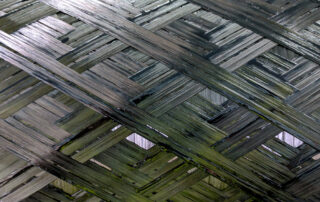

Fibres can be impregnated with resin as part of the process using an integrated resin metering system. This versatile machine can also wind prepreg tapes, towpreg or dry fibre.